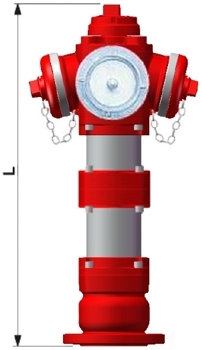

Overground hydrant DN100 TYPE C break-away system single closing - PN10 / PN16

| HYDRANTS | |

| TYPE : Overground

hydrant DN100 PN10 / PN16 - TYPE C - PN-EN 14384 with break-away system |

|

|

|

| Materials and construction characteristics : | |

| > Manufactured accordance to EN-14384 | |

| > Flange connections accordance to EN 1092-2 | |

| > Connection

couplings accordance to DIN 14318 at nominal

pressure PN10/16 STORZ 2xB + 1xA |

|

| > Hydrant can be equiped in other types of couplings acc. to domestic market specification | |

| > Patented efficited break-away system solution | |

| > Full

inner and outer heavy anti-corrosion epoxy paint with min. level of

250μm in RAL5015/3000 accordance to EN ISO 12944-5:2009, resistance for electrical breakdown 3kV including anti-UV addition |

|

| > Possibility

of hydrant elements assembly and disassembly without necessity to

surface interference surrounding |

|

| > Possibility of head turnover in range of 90º | |

| > Drainage takes place at the moment of complete closing of the hydrant | |

| > Roots

and roots covers made from aluminum or cast iron. Body and hydrant foot

made of grey or ductile iron, column as per below table options, mandrel made of stainless steel, mandrel nut made of brass with trapeze thread |

|

| > Quality and repeatability accordance to EN ISO 9001:2008 | |

| > Medium temperature - 40ºC | |

| Technical data : | |

| DN [mm] |

L [mm] |

RD

[mm] |

Weight [kgs] |

Catalogue no. |

Versions | Support column |

| 100 | 1900 | 1250 | 60 | 9819-100 | PN10/16 | Steel - in standard * INOX

* Zinc plated * Ductile iron |

| 100 | 2150 | 1500 | 63 | 9821-100 | PN10/16 | |

| 100 | 2450 | 1800 | 67 | 9824-100 | PN10/16 |

* - accordance to customer request

Reflecting continuous progress of product development we reserve right for further construction changes or to produce product accordance to customer request..

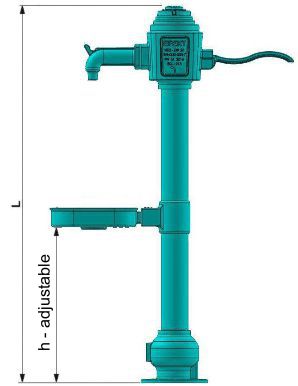

PUBLIC WATER FOUNTAIN TAP HYDRANT - Water Bubbler dn 20 PN10

| PUBLIC WATER FOUNTAIN TAP HYDRANT |

|

| TYPE : TAP HYDRANT DN20 - PN10 / PN16 - PN-EN 1074-1:2002 | |

|

|

| Application : |

|

| > Designed to use in water networks to serve drinking portablew water in public spaces | |

| > Manufactured accordance to EN- 1074-1 :2002 | |

| > Working pressure set at production 4 bars, other pressures accordance to customer request | |

| > Working pressure – EN 12266-1:1999 class A – PN16 | |

| > Water outlet - faucet diameter DN20 | |

| > Water network input connection 3/4 " | |

| > Upper head body and bottom body made of ductile cast iron EN-GJS-500-7 | |

|

> Square optional basket made of ductile cast iron EN-GJS-500-7 size 230x230 mm |

|

| > Bottom

support flange with 4 holes optionally allow to mount tap hydrant to

the support N bend DN65 / 4 holes |

|

| > Drainage takes place at the moment of complete closing of the hydrant | |

| > Full inner

and outer heavy anti-corrosion epoxy paint with min. level of

250μm in RAL5015/3000 accordance to EN ISO 12944-5:2009, resistance for electrical breakdown 3kV including anti-UV addition |

|

| > Hygienic certificate – PZH | |

| > Medium temperature : water 50ºC | |

| > Quality and repeatability accordance to EN ISO 9001:2008 | |

| Techical data : | |

| DN [mm] |

L [mm] |

RD

[mm] |

Weight

[kgs] |

Catalogue no. |

Versions | Support

column |

| 20 | 1975 | 1250 | 34,00 | 9119-20 | PN10/16 | Steel - in standard * INOX

* Zinc plated |

| 20 | 2225 | 1500 | 35,10 | 9115-20 | PN10/16 | |

| 20 | 2525 | 1800 | 36,20 | 9118-20 | PN10/16 |

* -

pod specjalne zamówienie

Ze względu na ciągły rozwój bazy

produktów, zastrzegamy sobie prawo do modyfikacji

wyrobów, lub wykonania go zgodnie z zapotrzebowaniem

klienta.

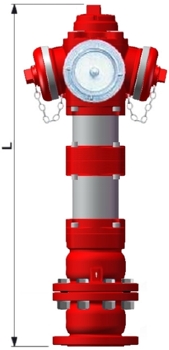

Overground hydrant DN150 with break-away system and double closing ( ball ) - PN10 / PN16

| HYDRANTS | |

| TYPE : Overground

hydrant DN150 PN10 / PN16 - TYPE C - PN-EN 14384 with break-away system - single closing |

|

|

|

| Materials and construction characteristics : | |

| > Manufactured

accordance to EN-14384 with destination of usage in industrial

plants where heavy Kv flow rate is required |

|

| > Flange connections accordance to EN 1092-2 | |

| > Connection

couplings accordance to DIN 14318 at nominal

pressure PN10/16 STORZ 2 x B + 2 x A |

|

| > Hydrant can be equiped in other types of couplings acc. to domestic market specification | |

| > Patented efficited break-away system solution | |

| > Full

inner and outer heavy anti-corrosion epoxy paint with min. level of

250μm in RAL5015/3000 accordance to EN ISO 12944-5:2009, resistance for electrical breakdown 3kV including anti-UV addition |

|

| > Possibility

of hydrant elements assembly and disassembly without necessity to

surface interference surrounding |

|

| > Possibility of head turnover in range of 90º | |

| > Drainage takes place at the moment of complete closing of the hydrant | |

| > Roots

and roots covers made from aluminum or cast iron. Body and hydrant foot

made of grey or ductile iron, column as per below table options, mandrel made of stainless steel, mandrel nut made of brass with trapeze thread |

|

| > Quality and repeatability accordance to EN ISO 9001:2008 | |

| > Medium temperature - 40ºC | |

| Technical data : | |

| DN [mm] |

L [mm] |

RD

[mm] |

Weight [kgs] |

Catalogue no. |

Versions | Support column |

| 150 | 1900 | 1250 | 70 | 9819-150 | PN10/16 | Steel - in standard * INOX

* Zinc plated * Ductile iron |

| 150 | 2150 | 1500 | 73 | 9821-150 | PN10/16 | |

| 150 | 2450 | 1800 | 77 | 9824-150 | PN10/16 |

* - accordance to customer request

Reflecting continuous progress of product development we reserve right for further construction changes or to produce product accordance to customer request..

| Downloads | |

Hydrant

data sheet Hydrant

data sheet |

Fire

chamber certificate

CNBOP Fire

chamber certificate

CNBOP Certyfikat

CE certificate Certyfikat

CE certificate Hygienic

certificate PZH Hygienic

certificate PZH |